Henry Cort, a British entrepreneur born in Lancaster around 1740, has long been regarded as discovering a metallurgical technique that was crucial to the Industrial Revolution. However, a new study has shown that Cort actually stole the practice from Black metal smiths in Jamaica.

The traditional story

Cort is a somewhat unknown figure despite the impact his “discovery” had on the industrial world he was part of. We do know that he and his family were deeply embedded in the enslavement system which was a “staple” of Lancaster at the time. At a young age, Cort inherited a fortune and went on to have a successful career in finance. In 1775, he took over the ironworks of a naval officer client who was in debt. Although it was located within the Portsmouth dockyards, a prosperous site of industry, Cort struggled to break even and lost a substantial amount of money.

Then, five years later, he was approached by the Royal Navy for a contract to supply iron hoops for barrels. The contract was a poor one, however, as it required Cort to take on the Navy’s scrap iron and somehow turn it into a high-quality product that could be used for the hoops. At the time, there was no known way to do this; yet again, it looked like Cort would be at a loss. But suddenly, in 1783, Cort patented a new process where scrap iron could be heated in a modified furnace and fed through special grooved rollers.

Aspects of this technique were already in circulation among metallurgists, but no one had combined them in the way that Cort’s patent did. The metal was still impure, but it was nevertheless significantly stronger and could be used for much larger constructions than just barrel hoops.

Unfortunately for Cort, things did not go well. To fund his operations, Cort borrowed a considerable sum of money from Adam Jellicoe, a Navy employee who had actually embezzled Navy funds. Upon Jellicoe’s death in 1789, Cort became liable for his debts, which forced him into bankruptcy. He quickly lost control of the patents, which was unfortunate for him but, so the story goes, a huge boon for British industry.

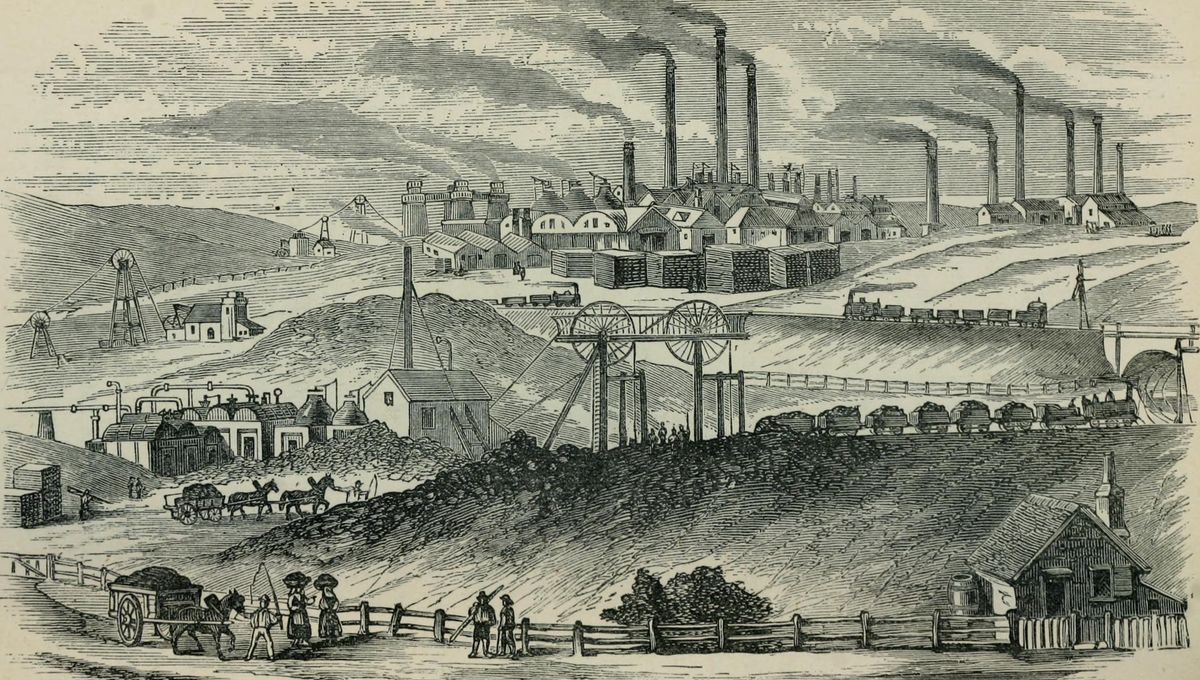

Now, his innovative technique was free to use by any budding industrialist and became the basis for suspension bridges, ship building, and textile mills.

The plot thickens

One of the enduring mysteries surrounding this story is how Cort apparently came up with his innovation. In 1783, he claimed that this novel approach was the result of “great study, labour, and expence [sic], in trying a variety of experiments and making many discoveries”. And yet there is no evidence of him undertaking any such experiments. It was like he had pulled the technique out of the air, but in reality, he had actually pulled it from across the Atlantic.

According to Jenny Bulstrode, a historian of science at University College London, Cort had stolen the idea from enslaved metal smiths in Jamaica.

During her research, Bulstrode found an archaeological report of a foundry in Jamaica that was using Cort’s technique before he apparently invented it. Through careful detective work, Bulstrode has now reconstructed a sequence of events that show how Cort had become aware of this foundry.

In 1772, John Reeder, an Englishman, established “Reeder’s Pen”, a lucrative foundry near Morant Bay in southeast Jamaica. This site produced boilers and rollers for the manufacturing of sugar and was manned by 76 Black metallurgists. In most instances, these workers had been taken from Africa by British slavers, but a few were Jamaican Maroons – individuals who had escaped slavery and preserved their freedom.

These Black metallurgists had perfected a method that allowed them to turn 3,000 tonnes of scrap iron into bars through furnaces and rollers. Crucially, the grooved rollers had been used for processing sugar cane but had never been used for iron.

According to Bulstrode, in the spring of 1781, Cort’s cousin John Cort visited Jamaica and was there at the time when one of the foundry workers was big news – a man named Kwasi, a Maroon, had killed a notorious freedom fighter called Three-Finger Jack. John would have certainly heard of this incident while he was there. Then, later that year, John’s ship experienced difficulties and headed to Portsmouth, where he met Henry.

Remember, Henry’s business was struggling at the time, and, coincidentally, so was Reeder’s Pen. It turns out that the foundry was actually illegal under British colonial law as anti-slavery rebels had used similar facilities to make weapons in the past. As such, in 1782, Reeder’s Pen was forced to shut down. But rather than disappearing from the world, the foundry was dismantled and shipped to Portsmouth.

“And the next thing you get is sugar rollers in Henry Cort’s foundry in Portsmouth,” Bulstrode told New Scientist.

The story represents a significant example of why the history of science, and history more generally, should listen to the voices of under-represented actors. In this instance, the expertise of enslaved people played a crucial and hitherto under-appreciated role in the history of the Industrial Revolution. From this perspective, it also shows the extent to which the ideas and intellectual inputs of enslaved people could be claimed by their owners.

Increasingly, scholars are coming to appreciate the knowledge and expertise of these traditionally marginalized people. According to Bulstrode, the regions of west and west-central Africa where the British slave trade operated were also “some of the most significant iron-working regions in world history”.

The paper is published in History and Technology.

[H/T: New Scientist]

Source Link: Icon Of The Industrial Revolution Stole Iron Technique From Enslaved Metallurgists