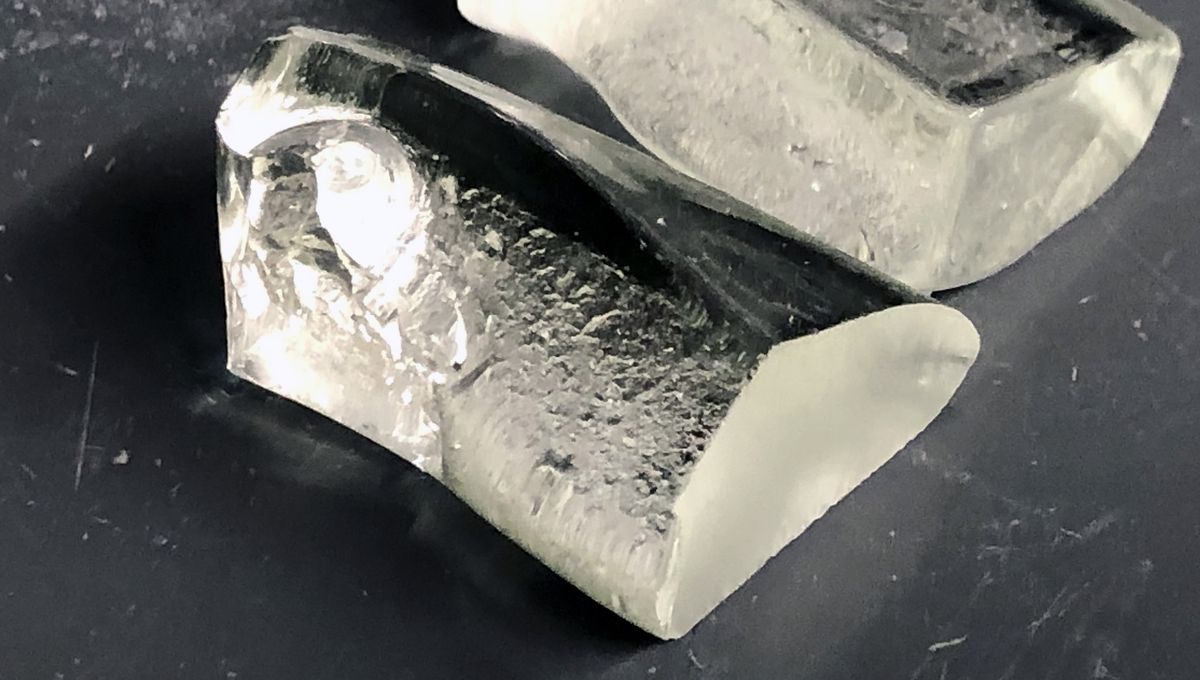

Researchers have presented a new material called LionGlass that promises to halve the carbon footprint of the standard soda lime silicate glass. It is also at least 10 times as crack-resistant as regular glass. The new material could be revolutionary.

The new glass reduced the carbon footprint in two ways. Regular glass is made by melting three components: quartz sand, soda ash, and limestone. Soda ash is sodium carbonate, and limestone is calcium carbonate. When they melt, the carbonates break apart, releasing carbon dioxide into the atmosphere. These components are eliminated in LionGlass.

But the main greenhouse gas emission comes from the actual melting. It takes a lot of energy to reach the temperatures to melt the sand, ash, and limestone together. LionGlass can be produced at lower temperatures, and cutting the temperature by 300 to 400 °C (540 to 720 °F) reduces energy consumption by 30 percent.

“Our goal is to make glass manufacturing sustainable for the long term,” lead researcher John Mauro, Professor of Materials Science and Engineering at Penn State, said in a statement. “LionGlass eliminates the use of carbon-containing batch materials and significantly lowers the melting temperature of glass.”

Regular soda lime silicate glass begins to form cracks under a load of 0.1 kilograms. That’s when the microcracks form on the surface that eventually lead to weak points, and the whole thing fracturing. However, the machine they used to test this did not affect the LionGlass at all.

“We kept increasing the weight on LionGlass until we reached the maximum load the equipment will allow,” said Nick Clark, a postdoctoral fellow in Mauro’s lab. “It simply wouldn’t crack.”

“Damage resistance is a particularly important property for glass,” Mauro added. “Think about all the ways we rely on the strength of glass, in the automotive industry and electronics industry, architecture, and communication technology like fiber optic cables. Even in health care, vaccines are stored in strong, chemically resistant glass packaging.”

The team is now testing different configurations, making LionGlass products that are thinner, since they are much stronger than regular glass. This is another way to make it cheaper and more environmentally friendly.

“We should be able to reduce the thickness and still get the same level of damage resistance,” Mauro said. “If we have a lighter-weight product, that is even better for the environment, because we use less raw materials and need less energy to produce it. Even downstream, for transportation, that reduces the energy required to transport the glass, so it’s a winning situation for everyone.”

Worldwide, glass manufacturing produces at least 86 million tons of carbon dioxide every year. The team has filed a patented application as a first step to commercialize the product.

Source Link: New Glass Has Half The Carbon Footprint And 10 Times The Strength Of Regular Glass