In the wild, baby animals like giraffes or horses will be up and walking within hours of birth – and maybe once, we would have found that impressive. Now, though? Nature can suck it. We’ve got it beat – with 3D-printed robots that can walk straight out of the machine that created them.

“Soft robotics holds transformative potential for healthcare, manufacturing, and human-machine interactions, but progress in research and toward reaching commercial goals is limited by the lack of standardized, scalable fabrication methods,” begins a new paper from researchers at the University of Edinburgh. “Our open-source flex printer platform addresses this gap, enabling rapid, reliable production of ultra-flexible soft robots with embedded fluidic logic […] which […] can walk out of the machine that made it.”

So, first things first: what even is “soft robotics”? Well, it’s pretty much what it sounds like: the design and building of robots out of pliable, “soft” materials, like plastics, silicone, or even gels and liquids. The result is a robot that’s more squishy, more flexible, or maybe just safer around humans than their less malleable cousins – and that makes them really useful for things like cutting-edge healthcare, space exploration, disaster relief, and so on.

Here’s the problem, though: this whole area is just so new. There’s barely been enough time for anyone to get properly good at it, or for certain techniques and designs to become standardized. Without an easy and cost-effective baseline, the actual applicability of soft robotics is somewhat stymied.

So it’s welcome news that these Scottish robot experiments have not only proved successful, but are also eminently cheap and easy to build – the entire setup, named the Flex Printer, can be assembled out of off-the-shelf parts totaling less than £400 (US $542), the researchers say.

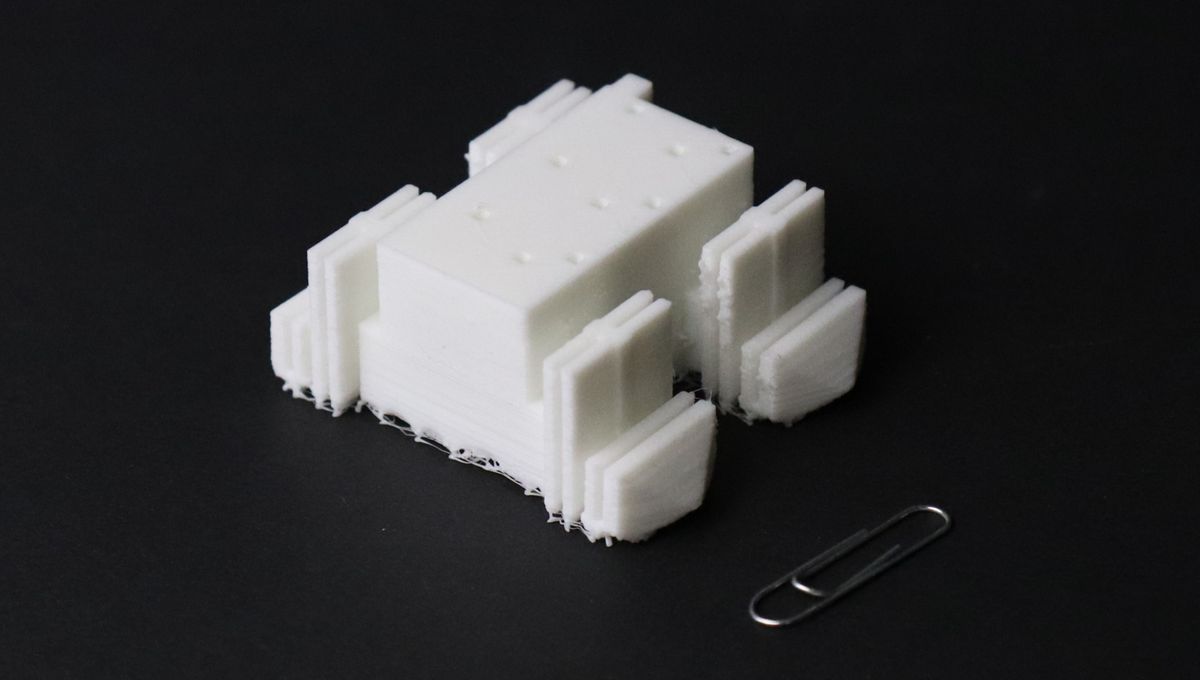

The result: a little, palm-sized robot – kind of reminiscent of some Baymax-Wall-E mashup – printed out of a soft plastic and powered by air pressure. Once printed, its umbilical air tube detaches, and off it walks.

The achievement is “a game-changer for engineers and artists alike,” said Maks Gepner, a PhD student at the University of Edinburgh’s Schools of Engineering and Informatics and lead engineer on the project, in a statement.

“It used to take years to figure out how to print using these materials,” he explained. “Using our new platform, anyone can now easily print things which were previously thought to be impossible […] Without the long-standing manufacturing and design bottlenecks holding it back, we believe soft robotics is ready to make a major real-world impact.”

These aren’t just empty platitudes. The team not only made their new system affordable and achievable, they also made it user-friendly, even for first-time users with little prior knowledge – even total beginners, they claim, should be able to create working robots within a few days. Even more noteworthy: the team’s own designs are all publicly available, and their paper is open access, in order to foster interest and collaboration in soft robotics more broadly.

“Ultimately, this platform lays the groundwork for widespread adoption and collaborative advancement in the field,” the paper boasts.

“By lowering technical and financial barriers, this work aims to democratize access to soft robotics,” the authors write, as well as “accelerate innovation, and foster new applications that can benefit society in both the short and long term.”

The paper is published in the journal Device.

Source Link: These Teeny Flexible Robots Can Literally Walk Out Of The Printer That Created Them