![]() Sourcing human tissue samples for biological investigations isn’t always easy. While they are ethically obtained through organ donation or from tissue that’s removed during surgical procedures, scientists are finding them increasingly difficult to get hold of.

Sourcing human tissue samples for biological investigations isn’t always easy. While they are ethically obtained through organ donation or from tissue that’s removed during surgical procedures, scientists are finding them increasingly difficult to get hold of.

And it’s not just because there’s a limited supply of human tissue samples. There’s also restricted availability of the specific size and type of tissue samples needed for the many projects taking place at any given time. That’s why we decided to address the issue by building our own low-cost, easily accessible printer capable of creating human tissue samples using one of the world’s most popular toys.

The emergence of 3D bioprinting has provided a potential solution to the difficulty in sourcing tissue samples. This technology involves loading “bio-ink”, which contains living cells, into a cartridge. That, in turn, is then loaded into the bioprinter. Once programmed, the bioprinter prints the cell-laden bio-ink to form 3D structures that aim to replicate the complex formation of biological tissue.

Unlike two-dimensional cell cultures grown on plates, which most of us still rely on for large parts of our research, bioprinters enable scientists to grow cells in three dimensions. And that better replicates the intricate architecture of human biology. In other words, bioprinting technology allows researchers to make more comparable models for studying healthy and diseased tissue.

The problem is that these machines come at an eye-wateringly high cost of some tens, even hundreds, of thousands of pounds. Few research teams, including ours, can stretch their budgets to cover that kind of expenditure, no matter how groundbreaking the technology promises to be.

That’s what led to us asking ourselves whether we could build our own affordable 3D bioprinter. The answer was “yes” and we decided to do so using Lego.

Anyone who’s ever tinkered with it will know that not only is Lego extremely cheap and versatile, but it’s also manufactured to very high precision with standardised parts that are globally accessible.

We also knew Lego had already been used to create traditional 3D printers. But what remained uncertain was whether we could take the basic notion of a Lego 3D printer – which prints solid 3D structures from plastic – and engineer one that could print soft biological material.

The output would need to be precise, reliable and stable for it to be of any use in our lab.

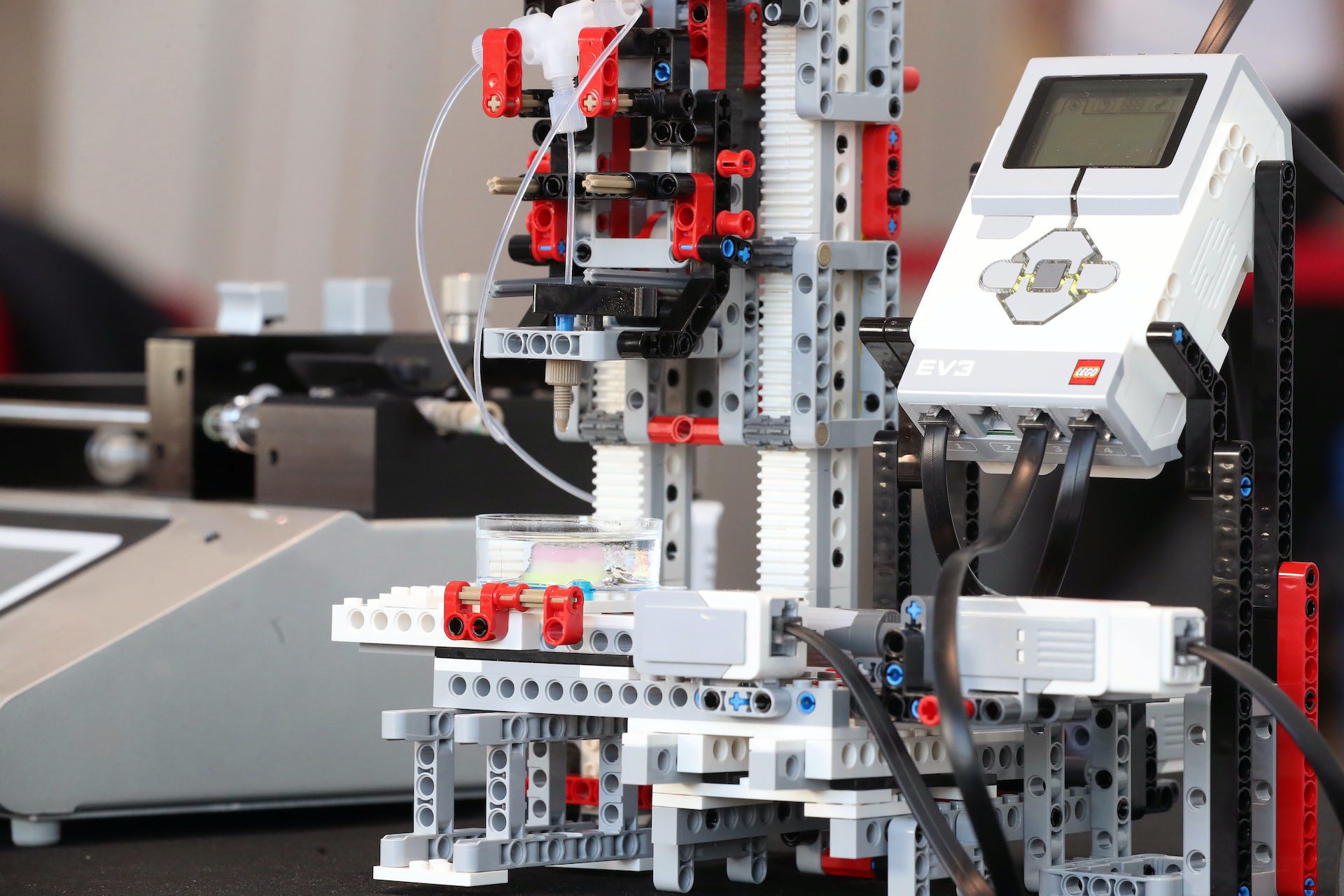

We got to work on our own affordable, high-spec bioprinter in a corner of our Cardiff lab using standard Lego bricks, their mechanical sub-brand, Lego Mindstorms and a lab pump, which is a device commonly found in research labs. A multidisciplinary team of engineers and biologists worked together to design, engineer, construct and program our bioprinter.

The 3D bioprinter is built from Lego and Lego Mindstorms. Image Credit: Cardiff University

Still in its infancy, our bioprinter, which cost £500 to build, achieves the required level of precision to produce delicate biological material. The way it does this is remarkably simple.

A nozzle ejects a gel-like substance, which is full of cells, onto a dish. At the heart of the device is a mini Lego Mindstorms computer. This device moves the dish backwards and forwards and side to side while moving the nozzle up and down mechanically as it extrudes the gel full of cells. These programmable movements build up layers of the cells to replicate the 3D structure of human tissue, layer by layer.

Our bioprinter is now being used to create layers of skin cells, working towards a full-scale skin model. It can also be modified by using different types of nozzles to print different types of cells, building a variety of complexities into the tissue samples. It’s an exciting opportunity to imitate both healthy and diseased skin, to look at existing treatments and to design new therapies to treat various skin diseases.

The future

Our bioprinter could not only provide us with an accurate representative model of human skin, it could also be used to add diseased cells to the healthy models we produce. This would enable us to study how skin conditions develop and how healthy and diseased cells interact. It would also enable us to see how skin diseases progress and how potential treatments can be developed.

We have provided details on how we built our Lego 3D bioprinter, giving clear instructions on how to reconstruct this device in any lab, anywhere in the world. At a time when research funding is so squeezed, we are offering an open source, accessible and affordable alternative to a vital piece of equipment that is beyond most researchers’ budgets.

Quite simply, we want our Lego bioprinter to enable researchers to conduct groundbreaking research because that will ultimately lead to a better understanding of biology and further improve human health.![]()

Sion Coulman, Senior Lecturer at the School of Pharmacy and Pharmaceutical Sciences, Cardiff University; Chris Thomas, Lecturer and Director of Postgraduate Research Studies at the School of Pharmacy and Pharmaceutical Sciences, Cardiff University, and Oliver Castell, Senior Lecturer at the School of Pharmacy and Pharmaceutical Sciences, Cardiff University

This article is republished from The Conversation under a Creative Commons license. Read the original article.

Source Link: We Built A Human-Skin Printer From Lego And We Want Every Lab To Use Our Blueprint